Fluxless TCB vs TCB

As interconnection pitches shrink below 10µm for advanced logic and memory applications, fluxless TCB solves the issues that standard TCB encounters with the flux.

Advanced packaging refers to the techniques used to package a microchip or semiconductor device in a compact and reliable way. Advanced packaging has become increasingly important in the semiconductor industry, as it enables higher levels of integration, reduces form factor, and improves electrical and thermal performance. Advanced packaging technologies are suitable for both logic and memory applications.

Advanced packaging involves the use of techniques such as wafer level packaging (WLP), 3d integration, through silicon via (TSV) and flip chip, among others. Wafer level packaging is a method in which the chips are packaged at the wafer level before they are separated. This technique enables higher throughput and lower cost compared to traditional packaging methods.

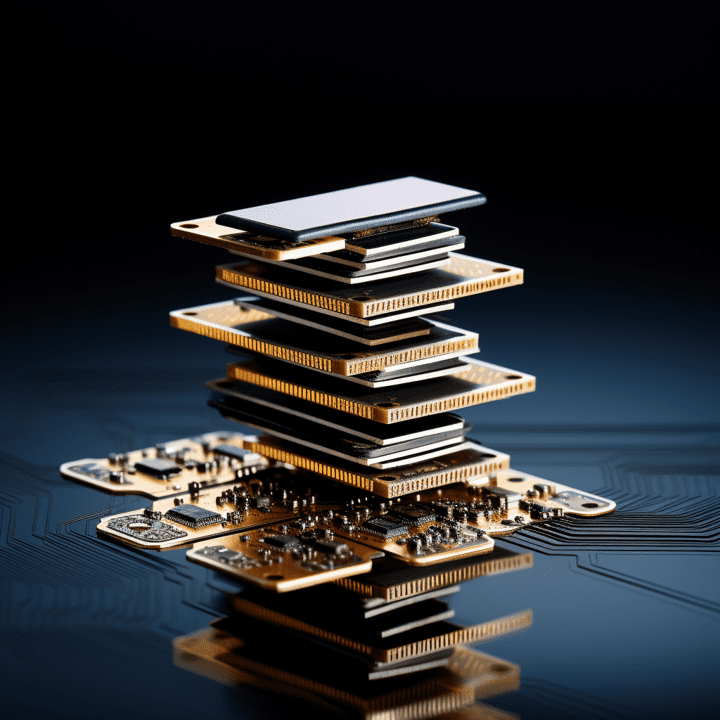

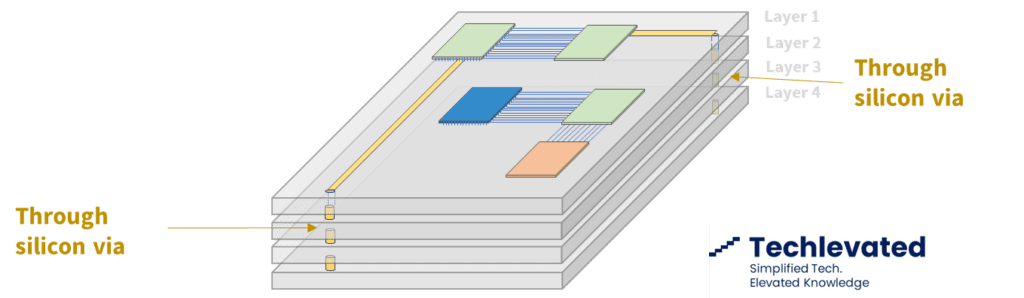

3D integration involves stacking multiple layers of chips vertically. The stacked chips are interconnected using TSVs, which are vertical interconnects that pass through the chip thickness. 3D integration enables higher performance in a smaller footprint, reducing the interconnect delay and power consumption.

Flip chip bonding, on the other hand, involves attaching the semiconductor device to a substrate by means of solder bumps. This technique is widely used in microprocessors, graphic processors, and other high performance ICs. Flip chip bonding enables higher performance and density compared to wire bonding.

In addition, advanced packaging also includes technologies such as system in package (SiP), fan out wafer level packaging (Fowlp), and embedded components. SiP involves the integration of multiple components, such as a microcontroller, sensors, and communication modules, onto a single package. FOWLP is a method in which the package size is reduced by redistributing the contacts from the silicon die to the package surface. Embedded components, such as capacitors and inductors, are integrated within the chip to improve performance and reduce the package size.

Advanced packaging technologies are essential in meeting the increasing demand for faster and more reliable electronic devices. The packaging technology used depends on the application and the performance requirements of the semiconductor device.

As interconnection pitches shrink below 10µm for advanced logic and memory applications, fluxless TCB solves the issues that standard TCB encounters with the flux.

The metal pitch refers to the distance between the centers of two adjacent metal interconnect lines on an integrated circuit (IC). Since transistors evolved into 3D strucrures, this measurement has lost significance.

The front-end and back-end are highly interdependent. A constant feedback loop between front and back-end engineers is necessary to improve manufacturing yields.

Built directly into the silicon, through silicon vias (TSV) facilitate 3D IC integration and allow for more compact packaging. They have become the default solution to interconnect different chip layers or to stack chips vertically.

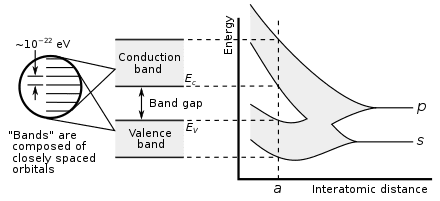

Silicon carbide (SiC) is used in electric vehicles due to its wide bandgap and great thermal conductivity. Gallium nitride (GaN) shares many characteristics with SiC while also minimizing RF noise.

GPU vs CPU is a parallelization vs complexity dilemma. While GPUs can manage very large parallel calculations, they struggle with linear, more heterogeneous tasks, where CPUs excel.